Back خرسانة مسبقة الإجهاد Arabic Formigón pretensao AST Ön dartılı beton Azerbaijani Formigó pretesat Catalan Předpjatý beton Czech Spannbeton German Hormigón pretensado Spanish Pingbetoon Estonian Hormigoi aurreatezatu Basque بتن پیشتنیده Persian

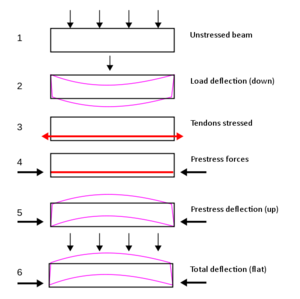

- Non-prestressed beam without load

- Non-prestressed beam with load

- Before concrete solidifies, tendons embedded in concrete are tensioned

- After concrete solidifies, tendons apply compressive stress to concrete

- Prestressed beam without load

- Prestressed beam with load

Prestressed concrete is a form of concrete used in construction. It is substantially "prestressed" (compressed) during production, in a manner that strengthens it against tensile forces which will exist when in service.[1][2]: 3–5 [3] It was patented by Eugène Freyssinet in 1928.[4]

This compression is produced by the tensioning of high-strength "tendons" located within or adjacent to the concrete and is done to improve the performance of the concrete in service.[5] Tendons may consist of single wires, multi-wire strands or threaded bars that are most commonly made from high-tensile steels, carbon fiber or aramid fiber.[1]: 52–59 The essence of prestressed concrete is that once the initial compression has been applied, the resulting material has the characteristics of high-strength concrete when subject to any subsequent compression forces and of ductile high-strength steel when subject to tension forces. This can result in improved structural capacity and/or serviceability compared with conventionally reinforced concrete in many situations.[6][2]: 6 In a prestressed concrete member, the internal stresses are introduced in a planned manner so that the stresses resulting from the imposed loads are counteracted to the desired degree.

Prestressed concrete is used in a wide range of building and civil structures where its improved performance can allow for longer spans, reduced structural thicknesses, and material savings compared with simple reinforced concrete. Typical applications include high-rise buildings, residential concrete slabs, foundation systems, bridge and dam structures, silos and tanks, industrial pavements and nuclear containment structures.[7]

First used in the late nineteenth century,[1] prestressed concrete has developed beyond pre-tensioning to include post-tensioning, which occurs after the concrete is cast. Tensioning systems may be classed as either monostrand, where each tendon's strand or wire is stressed individually, or multi-strand, where all strands or wires in a tendon are stressed simultaneously.[6] Tendons may be located either within the concrete volume (internal prestressing) or wholly outside of it (external prestressing). While pre-tensioned concrete uses tendons directly bonded to the concrete, post-tensioned concrete can use either bonded or unbonded tendons.

- ^ a b c Lin, T.Y.; Burns, Ned H. (1981). Design of Prestressed Concrete Structures (Third ed.). New York, US: John Wiley & Sons. ISBN 0-471-01898-8. Archived from the original on 8 February 2017. Retrieved 24 August 2016.

- ^ a b Federation Internationale du Beton (February 2005). fib Bulletin 31: Post-tensioning in Buildings (PDF). FIB. ISBN 978-2-88394-071-0. Archived from the original (PDF) on 8 February 2017. Retrieved 26 August 2016.

- ^ American Concrete Institute. "CT-13: ACI Concrete Terminology". American Concrete Institute. Farmington Hills, Michigan US: ACI. Archived from the original on 11 December 2016. Retrieved 25 August 2016. Post-tensioned concreted is "structural concrete in which internal stresses have been introduced to reduce potential tensile stresses in the concrete resulting from loads."

- ^ Billington, David (1985). The Tower and the Bridge. Princeton: Princeton University Press. ISBN 0-691-02393-X.

- ^ Warner, R. F.; Rangan, B. V.; Hall, A. S.; Faulkes, K. A. (1988). Concrete Structures. South Melbourne, Australia: Addison Welsley Longman. pp. 8–19. ISBN 0-582-80247-4.

- ^ a b Warner, R. F.; Faulkes, K. A. (1988). Prestressed Concrete (2nd ed.). Melbourne, Australia: Longman Cheshire. pp. 1–13. ISBN 0-582-71225-4.

- ^ Post-Tensioning Institute (2006). Post-Tensioning Manual (6th ed.). Phoenix, AZ US: PTI. pp. 5–54. ISBN 0-9778752-0-2.